|

Dillon -- Inventor of the mechanical dynamometer

|

|

Ships with dynamometer, shackles and pins, maximum pointer,

zero adjust for tare, carrying case or crate, calibration

certificate with curve of readings and certificate of

conformance. |

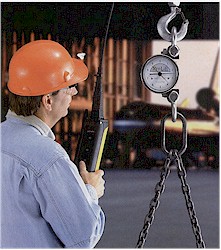

The Dillon APxtreme dynamometer was designed with input from

a lift specialist with truly critical demands -- a nuclear

fuel handler. The APxtreme takes rock solid performance and

reliability of Dillon's legendary AP

dynamometer to new heights. The APxtreme dynamometer is

perfect for other demanding environments such as critical

military duty, crane lifts and ultra-sensitive commercial

environments.

Engineered for Precision and durability

Great products begin with great design. Dillon

adopts a highly responsible and cautious approach to its

design engineering, backed up by the use of sophisticated,

modern techniques, such as Finite Element Analysis (FEA).

Dillon's philosophy results in the safest, most reliable

and most accurate dynamometers available . Given the critical

nature of APxtreme applications, for example, the design of

every capacity and configuration was confirmed to achieve

a 5:1 minimum ultimate safety factor via destructive testing.

In fact, the APxtreme load bars are designed to greatly surpass

this hurdle.

Dillon takes enormous care in choosing materials

used for its products. Only the best metals and coatings

are selected against our rigid engineering standards and

procedures. Taking this care a step further, Dillon manufactures

APxtreme load bars from only premium grade, certified and

traceable E4340 aircraft quality alloy steel. Each and every

APxtreme load bar must pass stringent Magnetic Particle Inspection

after machining. APxtreme load bars and shackles are electroless

nickel plated, a treatment that offers both exceptional corrosion

protection and typically permits periodicc future inspections

without costly coating removal.

APxtreme dynamometers undergo proof loading

to 150% of capacity to confirm strength, followed by a " three-run" calibration

procedure accuracy.

Feature for feature -- APxtreme is the Premium

dynamometer

Dillon sets the standard for mechanical dynamometers.

The APxtreme has the same great basic features of the Dillon

AP dynamometer, which include:

- Anti-parallax dial and pointer guarantees accurate readings

from any angle

- Industry leading accuracy to within 0.5% of capacity

- Choice of 5" or 10" (125 or 250 mm) dial sizes

- Tight heat treatment tolerances insure strength and long

life

- Premium bearings facilitiate smooth, repeatable operation

- Simple zero control tares easily

- Maximum hold indicator holds peak load

- Durable composite plastic or cast aluminum case resists

blows

- Wide operating temperature range (-50 to 140 F)

The APxtreme takes performance and reliability to new heights

addressing the needs of critical lift applications with these

enhancements:

- 5:1 ultimate safety factor in all capacities

- Exclusive material selection using even tighter tolerances

- Rounded pressure bar ends reduce binding with lift rigging

- Electroless nickel plating -- extra corrosion resistance

- Non-destructive examination of key components

- Lower weight and reduced headroom loss in high capacities

- Anchor shackles in all capacities

- Every unit proof-load tested to 150% of capacity

- Calibration confirmed by 3 runs

- Optional alarm and trip-point switching

- Additional specs

Storage boxes for Dillon APxtreme series

mechanical dynamometers

Dillon APxtreme auto control switch

This force switch allows automated control of motors, hopper

grates, conveyors or it can sound remote alarms. Preset at any desired load

point

Dillon APxtreme Klaxon signal alarm

Mounted on rear of the APxtreme dynamometer and sounds an

alarm at a preset load point

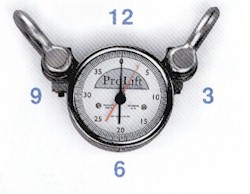

Dillon APxtreme Zero Positioning

The standard zero position is 9 o'clock for both the 5" and

10" dial sizes. Capacities up to 20,000 lb (10000 kg) can be supplied

with the zero at 13, 3 or 6 position if specified at the time of ordering.

Photo shows a non-standard 12 o'clock zero position

|