|

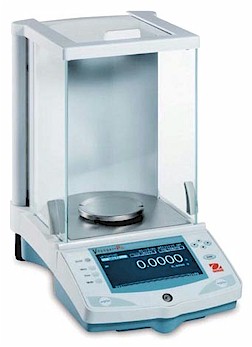

When your applications demand more than a standard balance, the new Ohaus Voyager® Pro is up to the task. Voyager Pro´s Advanced Applications simplify even the most complex laboratory measurements. Whether it’s determining the difference between initial and residual weights or calculating the density of solids and liquids, Voyager Pro eliminates the need for time consuming manual calculations and data logging.

Advanced in applications but not in operation. With Voyager Pro´s dot matrix

display and intuitive user interface, balance setup and use is effortless. For

superior weighing performance, Voyager Pro´s AutoCal™ feature automatically

calibrates the balance when it senses a temperature change sufficient enough

to affect weighing accuracy.

The Voyager Pro also includes an ergonomic leveling system; cursor keys for menu

navigation and balance setup; one function per key; auxiliary port; menu and

calibration lock-out switch; factory reset option; spill gutter; removable draft

shield doors.

Standard Features on both the Voyager Pro Analytical

and the Voyager Pro Precision

- AutoCal automatic internal calibration system

- The most advanced application modes in the industry, including:

- Statistics

- Formulation

- Differential Weighing

- Statistical Quality Control (SQC)

- Density Determination

- Pipette Calibration

- Standard application modes including:

- Percent Weighing

- Animal Weighing

- Check Weighing

- Filling

- Parts Counting

- Gross/Net/Tare Weighing

- Applications library to store and quickly recall past procedures

- Brilliant backlit high resolution dot matrix display with simple

navigation windows and menus to guide you through balance functions

- User selectable GLP/GMP outputs via RS232 to meet traceability

requirements

- User selectable filter, stability indicator and auto-zero tracking

for use in difficult environments

- Five operating languages--English, Spanish, French, German,

Italian

- Weigh-below hook for below-balance weighing applications

- Protective in-use cover and security bracket

- 2 year Ohaus warranty

- Click here for additional features

- Click here for more information

about Voyager Pro's applications

- Click here for more about the Voyager

Pro's weighing modes

Voyager

Pro Analytical Balances

| Model Number: |

VP64CN |

VP114CN |

VP214CN |

VP214DCN* |

|

|

|

|

| Price |

$2856.00

|

$3016.00

|

$3176.00

|

$3016.00

|

| Capacity x Readability |

62 g x 0.1 mg |

110 g x 0.1 mg |

210 g x 0.1 mg |

100/210 g x 0.1 / 1 mg |

| Weighing Modes |

gram, milligram,

ounce, troy ounce, carat, pennyweight, Hong Kong tael, Singapore

tael, Taiwan tael, mommes, grain, tical, Newton, custom |

| Application Modes |

Statistics, Formulation, Differential

Weighing, SQC, Density Determination, Pipette Calibration, Parts Counting,.

Animal Weighing, Check Weighing, Percent Weighing, Filling, Gross-Net-Tare

Weighing |

| Features |

Applications Library, RS232 Port, Auxiliary

Display Port, GLP Protocol, Selectable Operations Language, Selectable

Displayed Information Settings, Selectable Environmental Settings,

Selectable Auto-Print Settings, Integral Weigh Below Hook, Contrast & Brightness

Control, Protective In-Use Cover |

| Repeatability (std dev) (mg) |

0.1 mg |

0.1 / 0.5 mg |

| Linearity (mg) |

± 0.2 mg |

±0.2 / 0.5 mg |

| Tare Range |

Full capacity by subtraction |

| Stabilization Time |

4 seconds |

| Operating Temperature Range |

50° to 104°F (10° to 40°C) |

| Display |

LCD Dot Matrix with Back light -- 240 x 128 pixels |

| Power Requirements |

100-120 V AC, 220-240 V AC, 50/60 Hz |

| Pan Size |

3.5" (9 cm) dia |

Dimensions

(W x H x D) |

8.3" x 13.8" x 13.8" (21 x 35 x 35 cm) |

| Net Weight |

13.2 lb (6 kg) |

*moveable Fine Range™

top

Voyager Precision Balances

| Model Number: |

VP213CN |

VP413CN |

VP613CN |

*VP413DCN |

VP612CN |

VP2102CN |

VP4102CN |

VP6102CN |

*VP4102DCN |

VP4101CN |

VP6101CN |

VP8101CN |

|

|

|

|

|

|

|

|

|

|

|

|

Price |

$2308.00

|

$3016.00

|

$2316.00

|

$2756.00

|

$2236.00

|

$2292.00

|

$2548.00

|

$2276.00

|

$2756.00

|

$2068.00

|

$2236.00

|

$2344.00

|

| Capacity |

210 g |

410 g |

610 g |

100/410 |

610 g |

2100 g |

4100g |

6100 g |

1000/4100 g |

4100 g |

6100 g |

8100 g |

| Readability (g) |

0.001. |

0.001/0.01 |

0.01 |

0.01 / 0.1 |

0.1 |

| Repeatability (std dev, g) |

0.0005 |

0.0015 |

0.0005/0.005 |

0.005 |

0.01 |

0.01/0.05 |

0.05 |

| Linearity |

+/-0.002 |

+/-0.002/+/-0.005 |

+/-0.02 |

+/-0.04 |

+/-0.02/+/-0.04 |

+/-0.1 |

| Legal For Trade |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

YES |

| Weighing Modes |

gram, milligram, ounce, troy ounce,

carat, pennyweight, Hong Kong tael, Singapore tael, Taiwan tael,

mommes, grain, ticals, Newton, custom |

| Features |

Applications Library, RS232 Port, Auxiliary

Display Port, GLP Protocol, Selectable Operations Language, Selectable

Displayed Information Settings, Selectable Environmental Settings,

Selectable Auto-Print Settings, Integral Weigh Below Hook, Contrast & Brightness

Control, Protective In-Use Cover |

| Applications |

Statistics, Formulation, Differential

Weighing, SQC, Density Determination, Pipette Calibration, Parts

Counting,. Animal Weighing, Check Weighing, Percent Weighing, Filling,

Gross-Net-Tare Weighing |

| Operating Temperature |

50° to 104°F (10° to 40°C

) |

| Display |

LCD Dot Matrix with Back light -- 240

x 128 pixels |

| Power Requirements |

100-120 V AC, 220-240 V AC, 50/60 Hz |

| Platform Size |

4.7" (12 cm) diameter |

6.8" x 6.8" (17.2 x 17.2 cm)

with windshield |

Dimensions

(W x H x D) |

8.3" x 13.8" x 13.8"

(21 x 35 x 35 cm) |

8.5" x 4" x 13.8"

21.5 x 10.3 x 35 cm |

| Net Weight |

13.2 lbs (6 kg) |

11 lbs (5 kg) |

*Moveable Fine range™

| Key

Features |

- Superior Draftshield

A large 3-door draftshield is standard on all Voyager Pro Analytical

and Voyager Pro Precision balances with a 0.1/1 mg readability. The

draftshield design provides optimum draft protection from wind currents

for superior balance stability and reproducibility even in challenging

environments. the large chamber can accommodate larger vessels and

the removable side doors make it easy to clean

- Automatic Calibration

Voyager Pro's standard AutoCal™ calibration feature automatically

calibrates the balance when it senses a temperature change sufficient

enough to affect weighing accuracy. This feature assures accuracy while

saving operational time.

- Protective Cover

Voyager Pro's standard in-use cover is replaceable and protects the display

from harsh environments or spills that can ruin the balance.

- Large Brilliant Display

Voyager Pro's high-resolution dot matrix display with backlight enhances

viewing in any environment and has adjustable contrast and brightness

controls. The display illustrates the weighing results with large numeric

indicators and features user definable text fields to illustrate only

the information you want! The display also illustrates secondary units,

time and date.

- Communication Port with GLP/GMP Data Output

The standard RS232 communication port offers connectivity and it's GLP/GMP

data output capability prints time, date, balance, project, user ID,

calibration information and weighing information. Simply connect your

Voyager Pro to the optional Ohaus SF42 accessory printer and full traceability

of weighing procedures is achieved without the need for sophisticated,

expensive peripherals.

- Innovative Software

Voyager Pro's innovative user interface combines a dot matrix display

with scroll down menus, software prompts and 5 operating languages.

Balance setup and use is made simple and easy to follow with no training

required. The three application-specific soft-keys allow direct access

to features such as calibration, units, sample size and reference information

at the touch of a button. An applications library stores and quickly

recalls past procedures eliminating the need to re-establish application

parameters.

|

| Voyager

Pro Applications |

Advanced in applications but not in operation. With Voyager Pro's dot matrix

display and innovative user interface, balance setup and use is effortless.

For superior weighing performance, Voyager Pro's AutoCal™ feature

automatically calibrates the balance when it senses a temperature change

sufficient enough to affect weighing accuracy.

Statistical Quality Control (SQC)

The SQC feature is extremely useful during various types of process

filling operations when it is desired to monitor and control the process

to eliminate under and over filling. Provisions are made in the balance

to accommodate the weight of various packaging methods. During operation,

parameters of the packaged product are set into the balance such as

packaging weight, acceptable weight limits and non-acceptable weight

limits of the product.

These weight limits are identified as +T1, +T2, NOMINAL and -T1, -T2.

As samples are weighed and stored in the balance, a trend analysis

is developed and displayed on the balance. Up to 25 samples in a batch

with up to 10 batches are visible on a trend screen for quality control

purposes. Each batch of samples is shown on the display which indicates

the maximum/minimum standard deviation and mean values for each batch.

An ongoing examination of the relative deviation of the samples along

with other statistical data can be viewed and is stored. By observing

the results of the VIEW TRACE screen, you can effectively monitor the

filling process operation.

Statistics

Statistics are used when it is desired to compare a number of samples

along with other statistical data. A minimum of three samples are required

in this program. Statistics contains menu options which include: number

of samples, maximum, minimum, difference, sum, mean, standard deviation,

relative deviation, auto sample, and auto print. Weighing, Animal Weighing,

Check Weighing and Filling application modes can also be linked to

the Statistics mode to provide statistical data.

Differential Weighing

Differential weighing stores tare and weight values so samples can

be dried or processed and the difference in weight be calculated. Up

to 80 samples can be stored. The balance has the capability to work

with one or two different containers or no container at all.

Pipette Calibration

Pipette calibration checks the accuracy and precision values of pipettes

by weight analysis. An analytical balance is recommended for maximum

accuracy. The balance is capable of recording data from 3 to 30 samples

of each pipette tested. The density table for water is included and

if liquid is used for pipette calibration, Voyager Pro will accept

the alternate liquid's density in g/cc at current room temperature.

Since all calculations are made within the balance, it is also required

that you know the atmospheric pressure which has to be entered.

Density

Four methods of density determinations can be made with the Voyager

Pro balance. These are:

- Solids more dense than water

- Solids less dense than water

- Liquid density

- Porous material (impregnated with oil)

An accessory density determination kit is designed to be used with

Ohaus Voyager Pro balances. A built-in reference density table for

water at temperatures between 10° C and 30°C is included in

the balance software. When making density measurements, the material

should weigh at least 10.0 mg on an analytical balance and 100 mg on

a precision balance.

Formulation

Formulations can be named and have from 2 to 10 components specified.

Once named, they may be recalled and used at any time. Each component

of a given formulation can be specified as to its weight or percentage.

Each element of a formulation is shown on a dual bar graph as a percentage

and displays the desired weight. Thus, each component may be placed

on the pan until 100% is indicated.

Weighing Modes

Application Modes

- Differential Weighing

- Formulation

- Statistics

- Density Determination

- SQC

- Pipette Calibration

- Animal Weighing

- Parts Counting

- Percent Weighing

- Check Weighing

- Filling

- Gross/Net/Tare Weighing

|

Weighing Modes

- Milligrams

- Grams

- Kilograms

- Pounds

- Ounces

- Carats

- Troy Ounces

- Newtons

|

- Grains

- Mommes

- Taels (3)

- Ticals

- Pennyweights

- User Programmable Custom Unit

|

|

| Feature |

Advantage |

Benefit |

Advanced Weighing Applications Standard:

- Pipette Calibration

- Statistics

- SQC

- Formulation

|

Integration of applications into Voyager Pro

as a complete solution |

Provides simplified, automated measurement

analysis saving time and cost on additional equipment |

| AutoCal™ Internal Calibration Standard on all modes |

Voyager Pro models self-calibrate when they

sense temperature changes |

Ensures accurate measurements in all conditions |

Intuitive Keypad Layout

- Simple 2-butoon operation for basic weighing

- Soft key dynamic mapping for advanced operation

|

Easy to use. Accessible and repeatable operation.

Soft keys provide measurement flexibility. |

No training required to operate balance. Saves

time by allowing each mode to have dedicated keys. |

| Brilliant High-Resolution Graphic Display |

High contrast and large size are easy to

see and easy to read

Provides complete information. Enough space to hold

pertinent measurement information |

Allows easy viewing in all lighting conditions;

production lines, under vent hoods, etc. Less chance for

human error and creates less strain on eyes.

Eliminates uncertainty and potential for user errors.

Display provides through measurement details, reduces

amount of manual calculations |

| All Voyager Pro balances are NTEP approved Legal for Trade

(USA only) |

Balances can be used in either standard applications

or legal for trade. |

Flexibility in applications, customers

not forced into single path with purchase. Approved status

further verifies instrument fidelity and quality. |

|

|

|

Ohaus SF-42

Impact Printer

Ohaus

is introduces its newest compact impact printer, the SF42. Coupled with

an Ohaus balance featuring GLP functions such as the MB45, Explorer and

Navigator, the SF42 is the economical choice for providing a fully documented

audit trail. Audit trails required to meet today’s most stringent

standards for quality and verification. Ohaus

is introduces its newest compact impact printer, the SF42. Coupled with

an Ohaus balance featuring GLP functions such as the MB45, Explorer and

Navigator, the SF42 is the economical choice for providing a fully documented

audit trail. Audit trails required to meet today’s most stringent

standards for quality and verification.

- Compact design

- Quick and easy setup

- Ink ribbon prevents fading

- Self test mode assures proper functionality

- Compatible with Ohaus balances equipped with RS232 interface

General Specifications:

- Interface: Serial (RS232 Compatible)

- Printer Method: Impact Dot Matrix (Inked Ribbon)

- Character Format: 5 x 7 Dot Matrix

- Character Dimension: (in/cm) 0.04 x 0.10 / .11 x .26

- Character Density: 42 Characters per line

- Printing Speed: 40 lines per minute

- Paper Width: (in/cm) 2.25/5.7

- Power Adapter: AC adapter (110/120, 220/240 VAC) 50/60Hz

- Power: 9 V dc, 600mA, (center pin positive)

- Operating Temp. 32°to 104F°/0°C to 40°C

- Dimensions (W x H x D) (in/cm): 4 x 3.7 x 7.3 / 10.4 x 9.6 x 18.6

- Weight (lb/kg) 1.3 / 0.59 (without internal paper roll)

Interface Specifications:

- Connector: 25 Pin D type (Female)

- Baud Rate: Selectable (1200, 2400, 4800, 9600)

- Data Bit: 7 or 8

- Parity: Even, odd or none

- Stop Bit: Auto select

|

|

Ohaus

is introduces its newest compact impact printer, the SF42. Coupled with

an Ohaus balance featuring GLP functions such as the MB45, Explorer and

Navigator, the SF42 is the economical choice for providing a fully documented

audit trail. Audit trails required to meet today’s most stringent

standards for quality and verification.

Ohaus

is introduces its newest compact impact printer, the SF42. Coupled with

an Ohaus balance featuring GLP functions such as the MB45, Explorer and

Navigator, the SF42 is the economical choice for providing a fully documented

audit trail. Audit trails required to meet today’s most stringent

standards for quality and verification.