|

Dillon X-C Compression Force Gauge

Proven accuracy and ruggedness sets the Dillon X-C mechanical force gauge apart in the force measurement industry. The “D" shaped deflection beam is the heart of the Force Gauge system. Highly engineered materials with close machining tolerances and proper heat treatment provide optimum strength and spring characteristics.

Ideal for stand alone force applications or often used as the load defining component of a much larger system.

The Dillon X-C compression calibration force gauge comes in 8 capacities ranging from 50 lb to 25,000 lb or 50 to 10000 kg. All X-C force gauges feature accuracy of ±1% of full capacity, except the 25,000 (10,000 kg) capacity instruments which are accurate to ±2% of full capacity.

Load is applied against a hardened ball which rotates to maintain vertical alignment as pressure increases. The ball is held in place with a spring clip or retainer. A threaded mounting hole is located opposite the loading ball in the bottom of the beam.

Optional shockless dial indicator is available for installations involving the sudden application or release of force (maximum pointer cannot be supplied with shockless dial indicator). A maximum load pointer is also available, which remains at peak load until manually reset.

The Dillon X-C compression gauge comes with force gauge assembly, carrying case and compression-loading spherical ball fitting (note: case is not included with the 25000 lb, 50000 lb, 10000 kg or 20000 kg models).

Standard Compression Pounds Models

We offer Discounts

On All Dillon X-C Compression Force Gauges

For the Best Price Please: Call Us (800)832-0055 or Email Us

|

|

| Model |

30386-0035 |

30386-0043 |

30446-0033 |

30446-0017 |

30444-0019 |

30388-0017 |

30389-0016 |

30449-0014 |

|

|

|

|

|

|

|

|

| Price |

|

|

|

|

|

|

|

|

| Capacity & Dial Divisions |

50 x 1/2 lb |

100 x 1 lb |

250 x 2-1/2 lb |

500 x 5 lb |

1000 x 10 lb |

2000 x 20 lb |

5000 x 50 lb |

25000 x 250 lb |

Compression Models with Maximum Hand in Pounds

| Model with Maximum Hand |

30386-0159 |

30446-0090 |

30446-0074 |

30444-0050 |

30388-0058 |

30389-0057 |

30423-0055 |

30449-0055 |

|

|

|

|

|

|

|

|

| Price |

|

|

|

|

|

|

|

|

| Capacity & Dial Divisions |

100 x 1 lb |

250 x 2-1/2 lb |

500 x 5 lb |

1000 x 10 lb |

2000 x 20 lb |

5000 x 50 lb |

10000 x 100 lb |

25000 x 250 lb |

Compression Models with Maximum Hand in Kilogram

| Model with Maximum Hand |

30386-0183 |

30446-0181 |

30446-0082 |

30444-0068 |

30388-0066 |

30389-0065 |

30423-0063 |

30449-0063 |

|

|

|

|

|

|

|

|

| Price |

|

|

|

|

|

|

|

|

| Capacity & Dial Divisions |

50 x 0.5 kg |

100 x 1 kg |

200 x 2 kg |

500 x 5 kg |

1000 x 10 kg |

2000 x 20 kg |

5000 x 50 kg |

10000 x 100 kg |

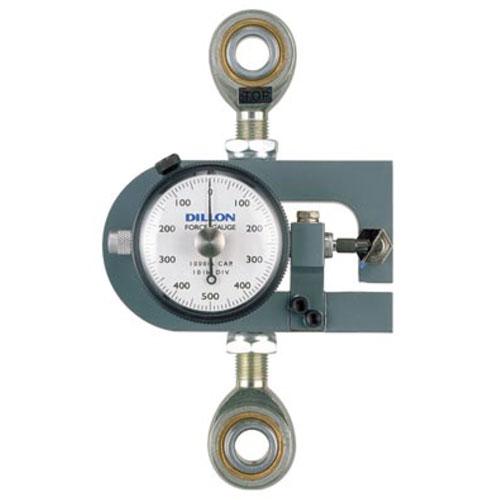

Dillon X-ST Force Gauge with Tension Calibration

Proven accuracy and ruggedness sets the Dillon X-ST mechanical force gauge apart in the force measurement industry. The “D" shaped deflection beam is the heart of the Force Gauge system. Highly engineered materials with close machining tolerances and proper heat treatment provide optimum strength and spring characteristics.

Ideal for stand alone force applications or often used as the load defining component of a much larger system. Ideal for stand alone force applications or often used as the load defining component of a much larger system.

The Dillon X-ST tension calibration force gauge comes in 9 capacities ranging from 25 lb to 10,000 lb or 10 to 5000 kg. Accuracy is ±1% of full range (note: for applications requiring capacities beyond 10,000 lb or 5000 kg in tension, consider the Dillon dynamometers).

Dillon X-ST tension force gauges in capacities through 2000 lb (1000 kg) are supplied with two rod end connectors. 5000 lb, 10000 lb, 2000 kg and 5000 kg capacities are equipped with convenient shackles and pins.

The Dillon X-ST tension gauge comes with force gauge assembly, carrying case and tension hardware.

Standard Tension Pounds & Kilogram Models

We offer Discounts

On All Dillon X-ST Tension Calibration Force Gauges

For the Best Price Please: Call Us (800)832-0055 or Email Us

|

|

| Model |

30443-0044 |

30445-0034 |

30445-0018 |

30276-0012 |

30440-0013 |

|

30443-0093 |

30445-0026 |

|

|

|

|

|

|

|

|

| Price |

|

|

|

|

|

|

|

|

| Capacity & Dial Divisions |

100 x 1 lb |

250 x 2-1/2 lb |

500 x 5 lb |

1000 x 10 lb |

2000 x 20 lb |

|

50 x 1/2 kg |

200 x 2 kg |

Tension Models with Maximum Hand in Pounds

| Model with Maximum Hand |

30443-0150 |

30445-0109 |

30445-0083 |

30276-0053 |

30440-0054 |

30442-0052 |

30441-0053 |

|

|

|

|

|

|

|

| Price |

|

|

|

|

|

|

|

| Capacity & Dial Divisions |

100 x 1 lb |

250 x 2-1/2 lb |

500 x 5 lb |

1000 x 10 lb |

2000 x 20 lb |

5000 x 50 lb |

10000 x 100 lb |

Tension Models with Maximum Hand in Kilograms

| Model with Maximum Hand |

30443-0176 |

30443-0184 |

30445-0182 |

30445-0091 |

30276-0061 |

30440-0062 |

30441-0061 |

|

|

|

|

|

|

|

| Price |

|

|

|

|

|

|

|

| Capacity & Dial Divisions |

25 x 1/4 kg |

50 x 1/2 kg |

100 x 1 kg |

200 x 2 kg |

500 x 5 kg |

1000 x 10 kg |

5000 x 50 kg |

Dillon X-PP Tension / Compression Calibration Push Pull Gauge

Proven accuracy and ruggedness sets the Dillon X-PP mechanical force gauge apart in the force measurement industry. The “D" shaped deflection beam is the heart of the Force Gauge system. Highly engineered materials with close machining tolerances and proper heat treatment provide optimum strength and spring characteristics.

Ideal for stand alone force applications or often used as the load defining component of a much larger system

The Dillon X-PP compression / tension calibration push pull gauge comes in 7 capacities in pounds ranging from 50-0-50 lb up to and including 5000-0-5000 lb and 4 metric capacities from 50-0-50 to 1000-0-1000 kg. Accuracy is ±1% of maximum dial reading (based on total capacity of both compression and tension scales).

Dillon X-pp gauges in capacities up to and including 1000-0-1000 lb or 500-0-500 kg are supplied with a set of self-aligning spherical rod end connectors for tension loading. Force is applied to connectors through a hardened steel pin which must be slip fit in connector holes.

2500-0-2500 and 5000-0-5000 lb and 1000-0-1000 kg capacity gauges are equipped with two shackle adapters, shackles and pins. Shackles must be removed when compression load is involved. Force is then applied against shackle pins in a suitable test setup.

The Dillon X-ST tension gauge comes with force gauge assembly, carrying case, compression loading spherical ball fitting for compression loading and tension hardware.

We offer Discounts

On All Dillon X-PP Push Pull Force Gauges

For the Best Price Please: Call Us (800)832-0055 or Email Us

|

|

| Pound Versions |

| Model |

Capacity & Dial Divisions |

Price |

| 30795-0014 |

|

50-0-50 x 1 |

6354

|

| 30796-0013 |

|

125-0-125 x 2.5 lb |

|

| 30798-0011 |

|

500-0-500 x 10 lb |

|

| 30800-0017 |

|

2500-0-2500 x 50 lb |

|

|

| Kilogram Versions |

| Model |

Capacity & Dial Divisions |

Price |

| 30796-0021 |

|

50-0-50 x 1 kg |

|

| 30798-0029 |

|

250-0-250 x 5 kg |

|

| 30800-0025 |

|

1000-0-1000 x 20 kg |

|

|

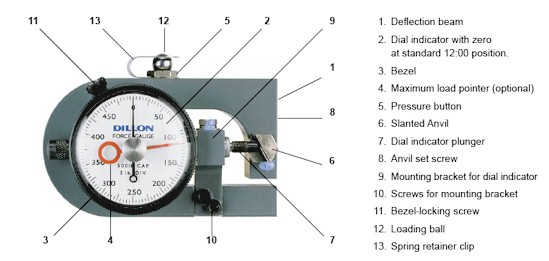

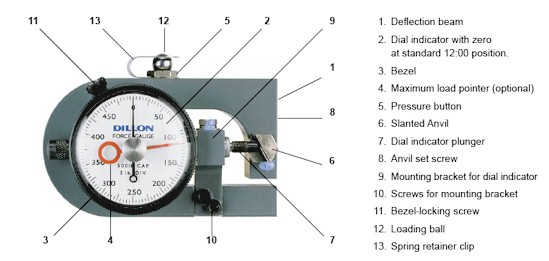

Dillon X-Series Force Gauge Parts Identification

Principle of Operation

A D-shaped deflection beam is the heart of the Dillon X force gauge. Machined to close tolerances, beams are heat treated to develop optimum strength and spring characteristics. High-strength aluminum is used in Dillon X series instruments through 200 lbs (200 kg). Ranges above this are fabricated from aircraft-quality alloy steel.

A precision dial indicator is mounted at the null point of the deflection beam. The indicator plunger rests against a slanted anvil at the open end of the beam, as shown in the photo. Under compression loads, the two halves of the beam tend to close. Tension force causes them to move apart. This action pushes the plunger inward, as determined by the slant of the anvil. Readings produced on the dial are in direct relation to applied load. The pointer revolves 360 degrees clockwise under compression or tension forces. Push-pull gauges read half scale (180 degrees) clockwise in compression, counterclockwise, 180 degrees from center zero under tension loads.

Low Beam Deflection

When measured across the center of top- and bottom-loading holes, the approximate beam deflection is as follows:

- 25 to 250 lb (10 to 100 kg) capacity - 0.019"

- 500 lb (200 kg) capacity - 0.016"

- 1000 lb (500 kg) capacity - 0.018"

- 2000 lb (1000 kg) capacity - 0.011"

- 5000 & 10000 lb capacity (2000 & 5000 kg) - 0.010"

- 25000 & 50000 lb capacity (10000 & 20000 kg) - 0.022"

Overload Rating

Accidental overloads of 30% of capacity can be safely sustained without injury to the dial indicator or deflection beam. All capacities feature a 5:1 safety factor.

General Information

- To reset zero, loosen knurled bezel-locking screw and rotate dial

- Dillon X series force gauges can be mounted horizontally, vertically or flat

- The baked enamel finish resists corrosion and rust

- Operating temperature up to 120 degrees fahrenheit

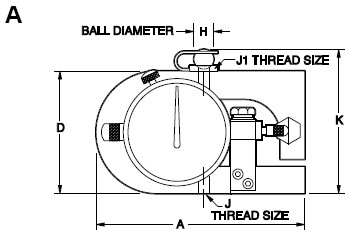

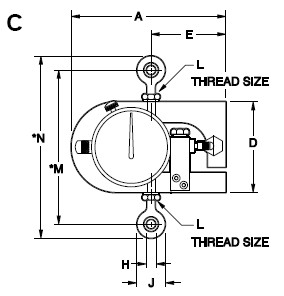

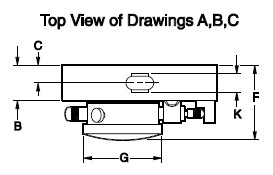

Dimensions

Model X-C Compression Gauges

| |

Pounds |

Kilograms |

A |

B |

C |

D |

E |

F |

G |

H |

J |

J1 |

K |

| A |

25 x 0.25 |

10 x 0.1 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/4-28" |

1/4-28" |

2.94" |

| 50 x 0.5 |

25 x 0.25 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/4-28" |

1/4-28" |

2.94" |

| 100 x 1 |

50 x 0.5 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/4-28" |

1/4-28" |

2.94" |

| 250 x 2.5 |

100 x 1 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/4-28" |

1/4-28" |

2.94" |

| 500 x 5 |

200 x 2 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/4-28" |

1/4-28" |

2.94" |

| 1000 x 10 |

500 x 5 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/4-28" |

1/4-28" |

2.94" |

| 2000 x 20 |

1000 x 10 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/2-20" |

1/2-20" |

3.44" |

| 5000 x 50 |

2000 x 20 |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2" |

2.25" |

0.38" |

1/2-20" |

1/2-20" |

3.44" |

| B |

10000 x 100 |

5000 x 50 |

5.87" |

1.87" |

0.94" |

3.94" |

2.75" |

3" |

3.62" |

0.75" |

7/8-14" |

7/8-14" |

4.5" |

| 25000 x 250 |

10000 x 100 |

6.56" |

2.38" |

1.18" |

4.68" |

3.31" |

3.63" |

3.62" |

1" |

1-14" |

1-1/2-12" |

5.5" |

| 50000 x 500 |

20000 x 200 |

7.59" |

2.75" |

1.38" |

5.5" |

3.28" |

4" |

3.62" |

1" |

1-14" |

1-3/4-12" |

6.31" |

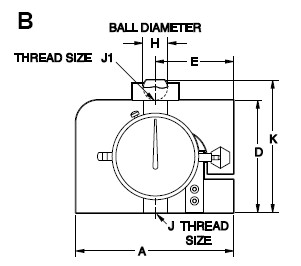

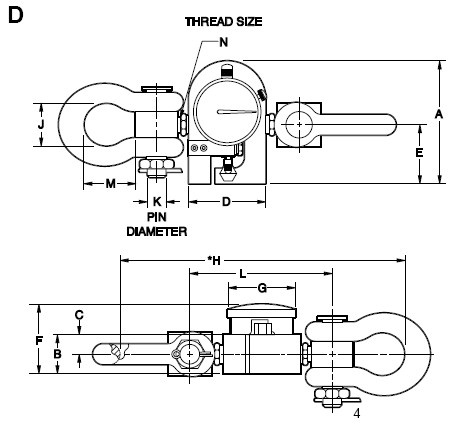

Model X-ST (Tension) and X-PP (Push-Pull) Gauges

| Pounds |

Kilograms |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

M |

N |

| - |

- |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2.03" |

2.25" |

0.25" |

0.75" |

0.38" |

5" |

4.25" |

1/4-28 |

| - |

- |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2.03" |

2.25" |

0.25" |

0.75" |

0.38" |

5" |

4.25" |

1/4-28 |

| 50-0-50 lb |

- |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2.03" |

2.25" |

0.25" |

0.75" |

0.38" |

5" |

4.25" |

1/4-28 |

| 125-0-125 lb |

50-0-50 kg |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2.03" |

2.25" |

0.25" |

0.75" |

0.38" |

5" |

4.25" |

1/4-28 |

| 250-0-250 lb |

125-0-125 kg |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2.03" |

2.25" |

0.25" |

0.75" |

0.38" |

5" |

4.25" |

1/4-28 |

| 500-0-500 lb |

250-0-250 kg |

4.25" |

1" |

0.5" |

2.5" |

2.06" |

2.03" |

2.25" |

0.5" |

1.31" |

0.62" |

6.94" |

5.62" |

1/2-20 |

| 1000-0-1000 lb |

- |

4.25" |

1" |

0.5" |

3" |

2.25" |

2.19" |

2.75" |

0.5" |

1.31" |

0.62" |

7.44" |

6.12" |

1/2-20 |

| 2500-0-2500 lb |

1000-0-1000 kg |

4.25" |

1" |

0.5" |

3" |

2.25" |

2.66" |

2.75" |

10.94" |

1.69" |

0.75" |

5.44" |

1.94" |

1/2-20 |

| 5000-0-5000 lb |

- |

5.88" |

1.88" |

0.94" |

3.94" |

2.75" |

3" |

3.62" |

12.69" |

1.69" |

0.75" |

71.9" |

1.94" |

7/8-1/4 |

| |

Tension (lb) |

Tension (kg) |

| C |

25 x 0.25 lb |

10 x 0.1 kg |

| 50 x 0.5 lb |

25 x 0.25 kg |

| 100 x 1 lb |

50 x 0.5 kg |

| 250 x 2.5 lb |

100 x 1 kg |

| 500 x 5 lb |

200 x 2 kg |

| 1000 x 10 lb |

500 x 5 kg |

| D |

2000 x 20 lb |

1000 x 10 kg |

| 5000 x 50 lb |

2000 x 20 kg |

| 10000 x 100 lb |

5000 x 50 kg |

|

Ideal for stand alone force applications or often used as the load defining component of a much larger system.

Ideal for stand alone force applications or often used as the load defining component of a much larger system.