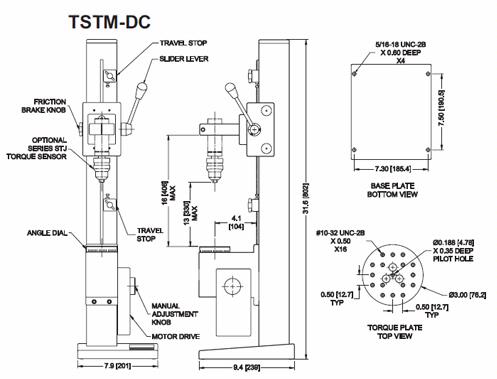

The TSTM-DC is shown in a cap torque test, with a Series STJ

torque sensor, BGI force/torque indicator, and G1023 universal

closure grip, and G1053 cap grip

|

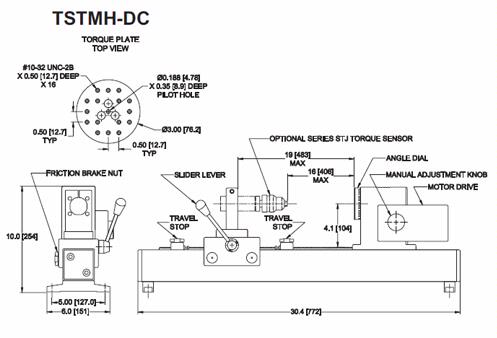

The TSTMH-DC is shown in a pen cap torque test, with a Series

STJ torque sensor, BGI force/torque indicator, and G1022 Jacobs

chuck grip

|

|

View Spec Cart Dimensions

The TSTM-DC is an advanced motorized torque test stand offering all the mechanical

specifications of the TSTM. The test stand is designed for a wide variety

of applications requiring up to 100 lbFin of torque, including closure torque

testing, fastener torque testing, and more. Modular design allows the stand to be

configured for a variety of torque sensors and gripping fixtures while a lever-operated

slider with travel stops makes engaging and disengaging samples quick and

efficient. The stand includes a torque loading plate with tapped holes for grip and

fixture mounting. Stepper motor design eliminate speed variation with load.

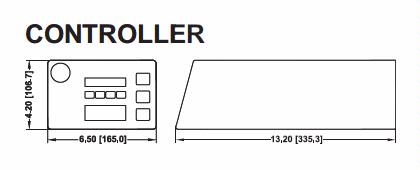

TThe TSTM-DCs controller adds a significant amount of sophistication, including

integrated angle display and output, programmable angle travel limits, an

extended speed range, PC control capability, programmable cycling, auto return,

overload protection, and other features.

- Maximum torque: 100 lbFin [11.3 Nm]

- Speed range: 0.01 - 15 RPM [0.05 - 90o/s]

- Speed accuracy: +0.2% of setting, +0% variation with load

- Integrated angle indication with programmable travel limits

- Maximum programmable travel limits: +999,999.9o / +2,777.77 revolutions

- Rotational travel accuracy: +0.7o

- Rotational travel repeatability: 0.1o

- Rotational travel resolution: 0.1o

- Universal power supply: 80-250 VAC

- Mounting holes for bench mounting

- Base may be removed for alternative mounting

- Grip / fixture mounting plate with 25 #10-32 threaded holes

- Slider travel rate: 1.047? [26.6 mm] / lever rev

- CE mark

Controller Features

Computer Controller

An RS-232 port is provided to interface with a PC. The ESM-DC accepts a number

of commands pertaining to test stand motion and force gauge functions*. The

following additional items are required for PC control:

- - Series BG force gauge

- - 09-1056 serial cable (see Optional Equipment)

- - 09-1143 multi-function cable (see Optional Equipment)

|

|

Overload ProtecTion

Protects a force gauge against overload (requires a Series BG force gauge and

09-1143 multi-function cable). The user programs the desired percentage of full

scale of the gauge. Adjustable analog output voltage setting allows the test stand

to interface with virtually any force gauge with analog output.

Auto Return

The crosshead moves to a limit switch or force set point (requires a Series BG

force gauge), stops, and reverses direction at maximum speed to the other limit

switch or set point.

Cycling / Dwel Time

The crosshead moves up and down between limit switches or force set points

(requires a Series BG force gauge). Configurable up to 99,999 cycles. Dwell time

allows the operator to program the amount of time, up to 9,999.9 seconds, in 0.1

second intervals, for which the crosshead pauses at limits.

Programmable UP / DOWN Button Functions

UP and DOWN button operation can be configured in three user-configurable

modes: Maintained: a short push produces continuous motion until STOP is

pressed, Momentary: crosshead moves only while the button is pressed, and

Auto: short push produces maintained motion, while holding down the button will

produce momentary motion.

Independent Up and Down Speeds

Programmable independent speeds for up and down directions

Selectable speed units of measurement (in/min & mm/min)

Password protection

Prevents unauthorized changes to test parameters

* Contains no integrated travel measurement. Travel information available only through the external ESM001 digital travel display, requiring an additional serial port on the PC. For an integrated solution with full PC control, including travel distance, see test stand model ESM301.

| Model |

TSTM-DC |

TSTMH-DC |

$8,075.00

|

$8,075.00

|

| |

Vertical |

Horizontal |

| Maximum force |

100 lbFin [11.3 Nm] |

| Maximum travel |

15.5" [394 mm] |

| Speed range |

0.01 - 15 RPM [0.05 - 90o/s] |

| Speed accuracy |

+0.2% of setting, +0% variation with load |

| Maximum programmable travel limits |

+999,999.9o / +2,777.77 revolutions |

| Rotational travel accuracy |

+0.7o |

| Rotational travel repeatability |

0.1o |

| Rotational travel resolution |

0.1o |

| Universal power supply |

80-250 VAC |

|

Integrated angle indication with programmable travel limits |

|

Mounting holes for bench mounting |

|

Base may be removed for alternative mounting |

|

Grip / fixture mounting plate with 25 #10-32 threaded holes |

|

Slider travel rate: 1.047? [26.6 mm] / lever rev |

|

CE mark |

TSTM-DC

TSTMH-DC

|