|

|

AND RV-10000 Tuning Fork Vibro Rheometer |

|

| Two thin sensor plates in a tuning fork arrangement are driven with electromagnetic force to vibrate at their natural (resonant) frequency of 30 Hz within the sample fluid. Viscosity is then calculated based on the proportional relationship between the viscous resistance of the sample fluid and the amount of electric current required to drive and maintain the sensor plates at a constant vibration amplitude more ... |

|

Scales >

Laboratory >

Viscometers

|

|

|

|

|

|

Features

A Significant Breakthrough in Viscosity Measurement of Non-Newtonian Fluids

What if you could evaluate the continuous behaviors of paints, creams, greases, polymers and many other kinds of non-Newtonian fluids more quickly, easily and precisely than you ever thought possible? With A&D’s tuning fork vibro method now capable of varying the shear rate, a whole new vista of materials research is wide open ahead of you—.

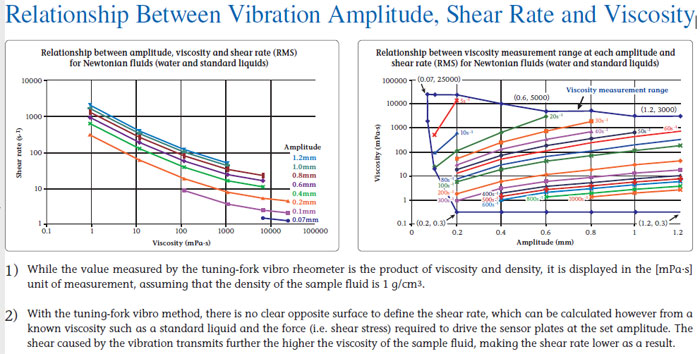

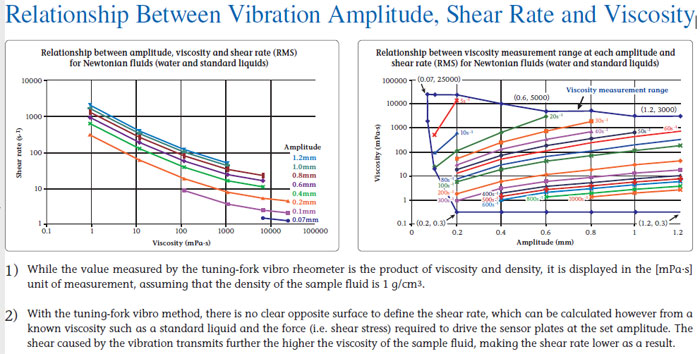

Vibration Amplitude Made Adjustable to Change the Shear Rate

By simple key operation, the sensor plate amplitude of the RV-10000 can be altered to eight levels (between 0.07 and 1.2 mm peak-to-peak), which create different shear rates. With this function, you can easily measure viscosity changes in response to varying shear rates.

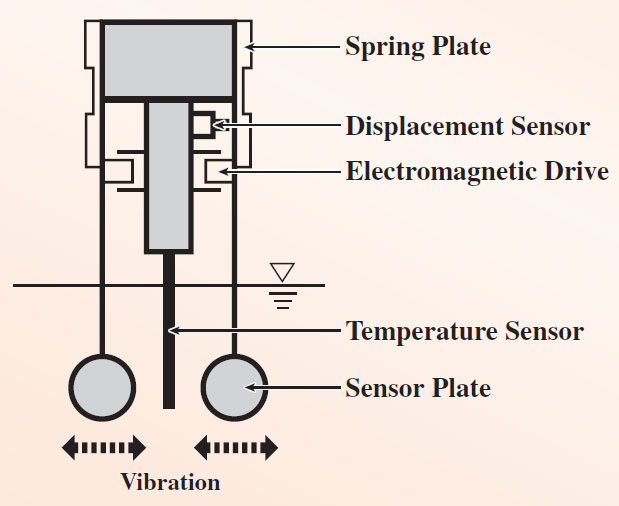

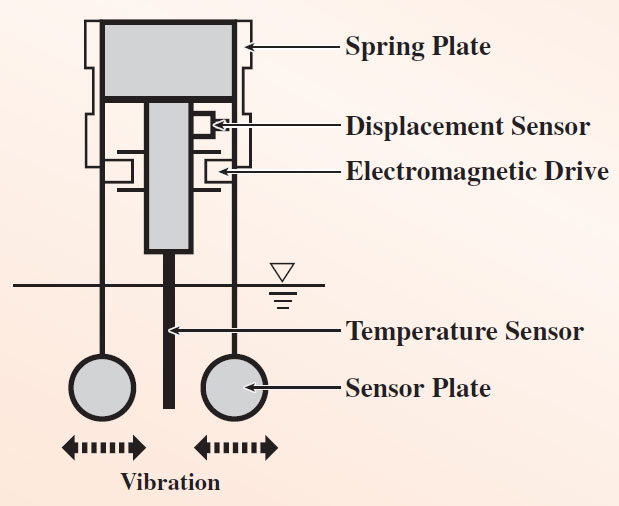

How the Tuning Fork Vibro Rheometer Works

Two thin sensor plates in a tuning fork arrangement are driven with electromagnetic force to vibrate at their natural (resonant) frequency of 30 Hz within the sample fluid. Viscosity is then calculated based on the proportional relationship between the viscous resistance of the sample fluid and the amount of electric current required to drive and maintain the sensor plates at a constant vibration amplitude.

The tuning fork vibro method is recognized as a Japanese industrial standard for viscosity measurement of liquids (JIS Z8803). The viscometer that uses this method is also accredited as a standard device for the Japan Calibration Service System (JCSS) along with capillary and rotational viscometers.

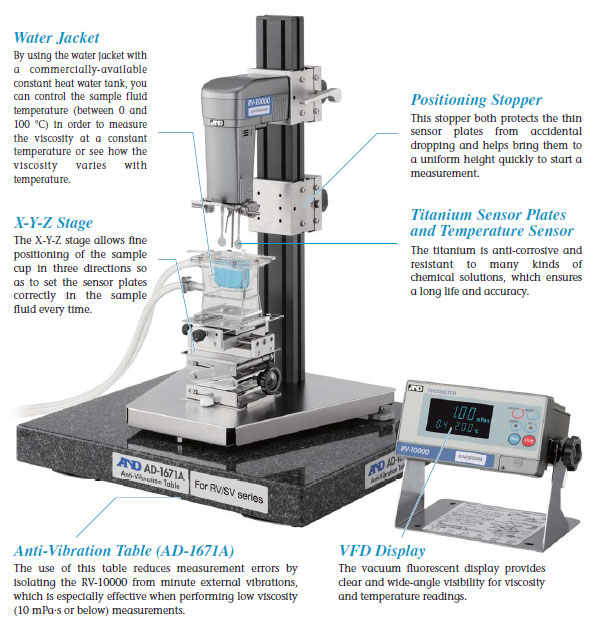

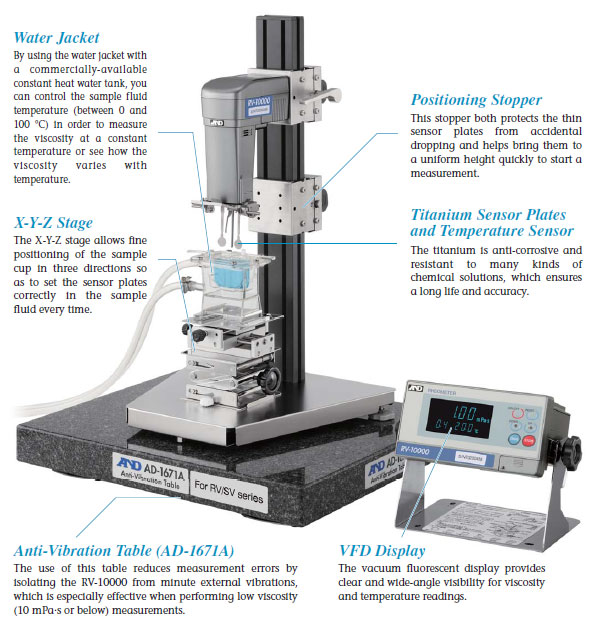

Easy Setup and Very Quick Measurement

Compared with conventional methods, it takes much less time for you to set the sample fluid, start measurement, and obtain the viscosity value (the RV-10000 requires only 20 seconds to stabilize). Moreover, since the sensor plates have a very small thermal capacity, they cause minimal temperature change to the sample fluid upon immersion, realizing fast and stable viscosity measurement

It is also very easy to clean the sensor after measurement – all you need to do is wipe off the sample residue with alcohol.*

*2 In the case of sample fluid sticking to the sensor, an off-the-shelf ultrasonic cleaner will be effective to remove it.

Simultaneous Measurements of Temperature and Viscosity

The temperature sensor (0 to 160 °C range) located between the two viscosity sensor plates allows measurement of viscosity’s dependence on temperature as accurately as possible.

Wide Dynamic Range of Measurements

Relationship Between Vibration Amplitude, Shear Rate and Viscosity Measurement Examples

The RV-10000 has a viscosity detection system that singly measures from very low to high viscosity in quick succession (max. 0.3 to 25,000 mPa.s), which makes the instrument highly versatile and able to cover measurement of various types of fluids by itself. It also allows continuous measurements of viscosity variation over time and/or temperature changes at differing shear rates .

Extremely High Sensitivity

The sensor sensitivity heightened through sharp resonance phenomena even detects viscosities around the level of water with unparalleled precision. Such sensitivity realizes measurements, for example, for finding the cloud point of surfactants and controlling the drinking sensation of beverages.

Excellent Repeatability

The RV-10000 achieves repeatability as high as 1% of the measured value (by standard deviation) for the entire measurement range, providing you with consistent results and enabling reliable comparisons of those results

Relationship Between Vibration Amplitude, Shear Rate and Viscosity

|

|

Other AND Weighing Viscometers SV-10 Series

|

Specifications

| Model |

RV-10000 |

| Measurement method |

Tuning fork vibro method (natural frequency at 30Hz) |

| Amplitude range |

0.07 to 1.2 mm (peak-to-peak at the tip of the sensor plate) |

| Viscosity measurement range |

Amplitude |

Viscosity range |

| 0.07 mm |

2,000 to 25,000 mPa.s |

| 0.1 mm |

20 to 25,000 mPa.s |

| 0.2 mm |

0.3 to 25,000 mPa.s |

| 0.4 mm |

0.3 to 12,000 mPa.s |

| 0.6 mm |

0.3 to 5,000 mPa.s |

| 0.8 mm |

0.3 to 5,000 mPa.s |

| 1.0 mm |

0.3 to 3,000 mPa.s |

| 1.2 mm |

0.3 to 3,000 mPa.s |

| Repeatability *5 *6 |

1% of the measured value (standard deviation) |

| Accuracy *5 *7 |

±3% (1 to 1000 mPa.s) when the amplitude is set to 0.4 mm |

| Minimum display |

| Range (mPa.s) |

Minimum display (mPa.s) |

Minimum display (Pa.s) |

| 0.3 to 10 |

0.01 |

0.0001 |

| 10 to 100 |

0.1 |

0.0001 |

| 100 to 1000 |

1 |

0.001 |

| 1000 to 25000 |

10 *8 |

0.01 |

|

| Viscosity measurement unit |

mPa.s, Pa.s, cP, P |

| Operating temperature |

10 to 40°C (50 to 104°F) |

| Minimum sample amount |

10 ml |

| Temperature display |

0 to 99°C/0.1°C (32 to 210.2°F/0.1°F); 100 to 160°C/1°C (212 to 320°F/1°F) |

| Temperature measurement accuracy |

0 to 20°C: ±1°C (32 to 68°F: ±1.8°F) |

| 20 to 30°C: ±0.5°C (68 to 86°F: ±0.9°F) |

| 30 to 100°C: ±2°C (86 to 212°F: ±3.6°F) |

| 100 to 160°C: ±4°C (212 to 320°F: ±7.2°F) |

| Display |

Vacuum Fluorescent Display (VFD) |

| Connection cable length |

1.5 m (between the sensor unit and the display unit) |

| Communication |

RS-232C as standard |

| Power supply |

AC Adapter |

| Power consumption |

Approx. 14 VA (including the AC adapter) |

| External dimensions / weight |

Sensor unit: 112 (W) × 132 (D) × 291(H) mm / approx. 0.8 kg |

| Display unit: 238 (W) × 132 (D) × 170 (H) mm / approx. 1.3 kg |

| Stand unit: 296 (W) × 314 (D) × 536 (H) mm / approx. 4.6 kg |

| Standard accessories |

AC adapter × 1, connection cable × 1, sample cup (capacity: 45 ml) × 5, small sample cup (capacity: 10 ml) × 5,

small sample cup cover × 5, glass sample cup (capacity: 13 ml) × 2, glass sample cup holder × 1, water jacket × 1,

WinCT-Viscosity × 1, RS-232C cable × 1, serial/USB converter × 1, stand for securing the sensor unit × 1, X-Y-Z stage × 1,

positioning stopper × 1, anti-vibration table × 1 |

* 5 When the sample cup (45 ml) is used.

* 6 Repetitive measurement with the sensor plates remaining in the sample fluid.

* 7 The value after calibration using a viscosity standard liquid at a temperature range between 20°C and 30°C with no condensation.

* 8 The unit switches to Pa.s

| Item |

Description |

| AX-SV-31-2.5 |

Standard liquid for calibration JS2.5 |

500 ml, with certificate in accordance with JIS Z8809 |

| AX-SV-31-5 |

Standard liquid for calibration JS5 |

| AX-SV-31-10 |

Standard liquid for calibration JS10 |

| AX-SV-31-20 |

Standard liquid for calibration JS20 |

| AX-SV-31-50 |

Standard liquid for calibration JS50 |

| AX-SV-31-100 |

Standard liquid for calibration JS100 |

| AX-SV-31-200 |

Standard liquid for calibration JS200 |

| AX-SV-31-500 |

Standard liquid for calibration JS500 |

| AX-SV-31-1000 |

Standard liquid for calibration JS1000 |

| AX-SV-31-2000 |

Standard liquid for calibration JS2000 |

| AX-SV-31-14000 |

Standard liquid for calibration JS14000/td>

|

| AX-SV-33 |

Sample cup, 45 ml, polycarbonate × 10 |

| AX-SV-34 |

Small sample cup, 10 ml, with cover, polycarbonate × 10 |

| AX-SV-35 |

Glass sample cup, 13 ml × 1 |

| AX-SV-37 |

Water jacket × 1, small sample cup with cover × 4 |

| AX-SV-38 |

Storage container, 60 ml, glass × 10 |

| AX-SV-39 |

Storage container, 120 ml, plastic × 20 |

| AX-SV-54 |

Cup set

Sample cup, 45 ml, polycarbonate × 5

Small sample cup, 10 ml, with cover, polycarbonate × 5

Glass sample cup, 13 ml × 2

Glass sample cup holder, stainless steel × 1

Water jacket × 1

|

| AD-8121B |

Compact printer |

| AD-1682 |

Rechargeable battery |

| AD-1671A |

Anti-vibration table for viscometers/rheometers |

| AD-1687 |

Environment logger |

|

|

|

|

|

|

Optional Accessories

more info

|

AND AD-1682 Rechargeable Battery Pack

Rechargeable Battery Pack for AND Weighing balances

|

|

more info

|

AND Weighing -AD-1687 - Weighing Environment Logger

| Data capacity |

Maximum 10,000 sets (including date and time) |

| Interval time |

1, 2, 5, 10, 15, 20, 30 seconds, 1, 2, 5, 10, 15, 20, 30, 60 minutes |

| Power supply |

Two LR6 (AA) batteries, RS-232C, or USB |

| Battery life |

Approx. 6 months (with measurement interval at 1 minute, alkaline batteries) |

| Clock accuracy |

Maximum ±1 minute/month |

| Compatible operating systems |

Windows 2000 / XP / Vista / 7 (32 / 64 bit) |

| Operating environment |

0 to 60 °C / 32 to 140 °F, 85% RH or less (no condensation) |

| Dimensions |

127 (W) × 90 (H) × 36 (D) mm (including the protective cover) |

| Weight |

Approx. 275 g (including batteries and the protective cover) |

| Standard accessories |

Three RS-232C cables for weighing instruments (9-pin D-Sub, 25-pin D-Sub, and 7-pin DIN, 1 m), USB cable (1 m), Two LR6 (AA) batteries (for operation check), Protective cover, Instruction manual |

| Sensor |

Resolution |

Measurement range |

Accuracy |

| Temperature |

0.1 °C ,0.1 °F |

0.1 °F 0 to 60 °C ,32 to 140 °F |

32 to 140 °F ±0.5 °C (20 to 30 °C),±0.9 °F (68 to 86 °F) |

| Relative humidity |

0.1% RH |

0 to 100% |

<±3% (20 to 80%)/td>

|

| Barometric pressure |

0.1 hPa |

500 to 1100 hPa |

hPa ±3 hPa (0 to 60 °C) |

| Vibration |

1 mG |

0 to 2000 mG |

±20%, static acceleration |

|

|

|

|

|

|

|

|

|