|

|

RADWAG UYA 4Y.KO Manual Mass Comparator 5.1 g x 0.0001 mg |

|

| Mass comparator UYA 4Y.KO series, comprises two components. One of them holds the electronic module, and the other precise mechanical measuring system. more ... |

|

Laboratory Equipment >

Analytical Balances >

Mass Comparators

|

Specifications Chart

|

Have Questions?

Our Staff will be glad to help |

Capacity x Readability

5.1 gx 0.0001 mg

Pan Size

16 mm (Diameter)

|

|

|

|

|

|

|

|

|

Features

Mass comparator UYA 4Y.KO series, comprises two components. One of them holds the electronic module, and the other precise mechanical measuring system. Such solution guarantees elimination of temperature influence (warming of electronic elements) on the comparators indications. The comparator features an aesthetic, cylindrically shaped weighing chamber with glass draft shield and automatic door opening system. All elements of the weighing chamber are manufactured from glass or metal to minimize the influence of electrostatic charges on the measuring result.

Mass comparators are used for both, ensuring traceability of mass measurements and verification of weights in accordance with the principles of legal metrology. RADWAG Mass Comparators have gained recognition among Accredited Calibration Laboratories in many countries.

- Features Effective and Excellent Measurement UYA 4Y.KO mass comparators allow to compare 1 g - 5 g weights of class E1 and lower. The devices are characterised by the highest repeatability, 0.1 µ.

- Maximum Comfort of Operation UYA 4Y.KO mass comparators are equipped with an auto-open weighing chamber that is highly resistant to air drafts. The chamber is made of glass, this makes the compared weight visible from any angle

- Excellent Measurement Repeatability Each UYA 4Y.KO mass comparator is equipped with an additional external anti-draft chamber by standard, use of this accessory allows to minimize the influence of temperature change and air drafts on the measurements. Since all the external chamber components are made of either glass or metal the effect exerted by an electrostatic field on the weighing result is reduced.

- Dedicated Software Specially designed RMCS computer software enables comprehensive realisation of calibration procedures in laboratory. The system manages the whole calibration process, starting from the moment the order is placed, through procedure performance, to the moment of issuing the calibration certificate.

Functions

- Mass comparator

- Ambient conditions measurement

- Proximity sensors

- Replaceable units

- Multilingual menu

- Autotest

- Automatic sliding door

Weight:

20.00 lb

|

|

Specifications

| Model |

AK-4/100 |

| Capacity x Readability |

5.1 g x 0.0001 mg |

| Repeatability for nominal load* |

0.4 µ(5 g) |

| Repeatability for small load* |

0.25 µ (100 mg) |

| Stabilization time |

30 s |

| Adjustment |

Internal Calibration |

| Electric compensation range |

0 ÷ 5.1 g |

| Eccentricity (for test weight) |

1 d / 1 mm |

| OIML calibration range E1 |

1 mg ÷ 5 g |

| OIML calibration range E2 |

1 mg ÷ 5 g |

| OIML calibration range F1 |

1 mg ÷ 5 g |

| OIML calibration range F2 |

1 mg ÷ 5 g |

| OIML calibration range M1 |

1 mg ÷ 5 g |

| OIML calibration range M2 |

1 mg ÷ 5 g |

| Display |

5.7" color resistive touch screen |

| Keypad |

8 keys |

| Ingress protection - indicator |

IP 43 |

| Touch-free operation |

2 programmable sensors |

| USB-A |

2 |

| Ethernet |

10 / 100 Mbit |

| RS-232 |

2 |

| Wi-Fi |

802.11 b/g/n |

| IN/OUT |

4 x IN, 4 x OUT |

| Power supply |

110 ÷ 230 V AC / 50 ÷ 60 Hz |

| Operating temperature |

+15 ÷ +30 °C |

| Operating temperature change rate |

± 0.5 °C / 12 h (± 0.3 °C / 4 h) |

| Relative humidity variations |

± 2% / 4 h |

| Relative humidity*** |

40 ÷ 60% |

| Transport and storage temperature |

–20 ÷ +50 °C |

| Weighing pan dimensions |

ø 16 mm |

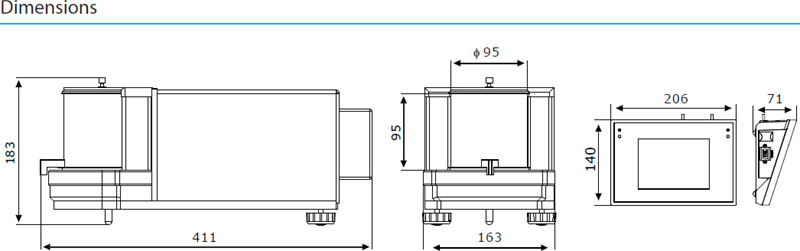

| Mass comparator dimensions** |

411 x 163 x 183 mm |

| Indicator dimensions** |

206 x 140 x 71 mm |

| Anti-draft chamber dimensions** |

560 x 250 x 350 mm |

| Mass comparator net weight |

9.1 kg |

| Mass comparator gross weight |

16.6 kg |

| Anti-draft chamber net weight |

7.6 kg |

| Anti-draft chamber gross weight |

10.9 kg |

| Mass comparator packaging dimensions** |

660 x 660 x 455 mm |

| Anti-draft chamber packaging |

820 x 840 x 630 mm |

* repeatability is expressed as a standard deviation determined for 6 ABBA cycles

** non-condensing conditions

*** dimensions: length x width x depth

**** optional design

Accessories - Call for more info

Weighing Tables

granite anti-vibration table

anti-vibration table for laboratory balances

professional weighing table |

Ambient Conditions

THB-S or THB-P sensor |

Peripheral Devices

Epson dot matrix printer

barcode scanner

WD-5/3Y LCD display (backlit) |

Cables, Converters

RS-232 – P0108 computer cable

RS-232 – P0167 computer cable

RS-232 – P0151 Epson printer cable |

Electrical Accessories

power supply with ZR–02 battery |

Anti-Draft Chambers

MYA anti-draft chamber |

Dedicated Software (not included) - Call for more info

RMCS System

- performance of calibration procedures in a laboratory from the moment the order is placed, to the moment of issuing a calibration certificate

- compatible with THB sensors enabling recording ambient conditions

- export of report results to various files

- archiving calibration protocols, orders, certificates and ambient conditions

RADWAG Remote Desktop

- remote control of the mass comparator using computer, telephone or tablet

- sending text messages

- version for Windows 10 and Android systems

R-LAB

- collecting measurements

- carrying out statistical analysis of measurements

- customized graphs and reports

Parameters Editor

- remote change of parameters

- remote on-line preview of the display

- displaying current mass indication

- software update

- file loading, editing and saving parameters to a file

- import and export of parameters

- interfaces: RS232, Ethernet and Wireless Connection

- quick and easy edition of balance parameters using computer

|

|

|

* within the 48 continental US States

|

|

Optional Accessories

more info

|

RADWAG RMCS PC software for mass metrology

View Data Sheet (PDF)

More about the/RMCS

RMCS system, designed by RADWAG, is dedicated to management of calibrating and testing procedures in a laboratory from the moment of accepting an order, through its progress and until issuing a calibration certificate. The software manages the complete calibrating and testing process.

The operation of mass comparators in connection with the software for network management of calibration process provides improved efficiency, reliable measurement results and complete documentation from calibration process, together with lower labour costs.

The system enables initiating the calibration procedure by ordering a task to a mass comparator, and autonomous executing calibration process on a mass comparator. In both cases, data is transferred to the software for the purpose of registering, controlling and finally issuing a calibration certificate.

Mass comparators linked in the RMCS system autonomously cooperate with THB ambient conditions monitors enabling recording major ambient factors like temperature, humidity and atmospheric pressure throughout the control process. The modules are detachable from the mass comparators for calibration and adjustment of their sensors.

Data on current ambient conditions is displayed in real time on mass comparator’s display. The data is also sent do RMCS software for control and archiving purposes.

System modules:

Ambient conditions monitoring module:

- Installed and in direct cooperation with a mass comparator;

- Enabling recording ambient conditions (temperature, humidity, atmospheric pressure) and calculating air density;

- Continuous monitoring of ambient conditions in direct vicinity of a mass comparator and its weighing chamber;

- Graphic presentation of ambient conditions on mass comparator’s display.

Weighing module:

- Automatic and manual mass comparators used as components of the RMCS system;

- Access and management of databases on: standards, test objects, from the level of RMCS software;

- Execution of calibration tasks ordered in the RMCS software;

- Self test procedure determining mass comparator’s repeatability parameter;

- Transfer of measurement results to the software memory.

Calculating and data storage module:

- Sending tasks to mass comparators;

- Downloading data on mass and ambient conditions from mass comparators;

- Operation on databases of clients / tasks / standards;

- Monitoring of future calibration dates;

- Database of accomplished calibrations, printouts and saved documentation.

Software functions:

RMCS functionality:

- Complete management of a metrological laboratory calibrating mass standards and weights with application of Y series of RADWAG mass comparators;

- Calibration using ABBA and ABA methods;

- Application of MS SQL database for network supervision of multiple computer stands;

- Complete management of calibration orders;

- Extended database of mass standards and test objects;

- Extended database of clients, operators and users;

- Database of manual and automatic mass comparators;

- Database of calibration orders;

- Managing pending tasks based on issued calibration orders;

- Planning tasks and orders execution;

- Weight checking procedure without an order – Quick Check option;

- Manual or automatic calibration of test objects;

- Cooperation with RADWAG automatic mass comparators;

- Bilateral data synchronization with RADWAG mass comparators;

- Reporting from calibration process;

- Issuing calibration certificates according to pre-defined template;

- Exporting report results to various file formats: PDF, MS Word, Excel;

- Record of events;

- Register of orders and calibration certificates;

- Saving copies of all calibration protocols, orders, calibration certificates and records of ambient conditions;

- Secured access to the software – log in procedure using password.

|

|

more info

|

RADWAG SAL/STONE/C Granite Anti-Vibration Table 1000 x 650 x 815 mm Powder Coated Steel

Table SAL/STONE/C is designed for ensuring stable operating conditions for high precision measurements. The table top is manufactured from polished granite and it is based on mild steel, metal construction.

- Anti-Vibration Construction Granite top on a stainless steel construction enables convenient operation and eliminates ground vibrations that may influence measurement accuracy.

- Base Temperature The top ensures stable temperature of the base and the highest accuracy and repeatability of measurements.

- Working Space Large surface enables carrying out complicated measuring processes on several devices.

- Various Applications The weighing tables are intended for operation in industry and laboratory

Set Content

Top (granite)

Base (stainless steel or powder-coated)

Vibration-resistant feet

Adjustable feet

|

|

more info

|

RADWAG SAL/STONE/H Granite Anti-Vibration Table 1000 x 650 x 815 mm Stainless Steel

Table SAL/STONE/C is designed for ensuring stable operating conditions for high precision measurements. The table top is manufactured from polished granite and it is based on mild steel, metal construction.

- Anti-Vibration Construction Granite top on a stainless steel construction enables convenient operation and eliminates ground vibrations that may influence measurement accuracy.

- Base Temperature The top ensures stable temperature of the base and the highest accuracy and repeatability of measurements.

- Working Space Large surface enables carrying out complicated measuring processes on several devices.

- Various Applications The weighing tables are intended for operation in industry and laboratory

Set Content

Top (granite)

Base (stainless steel or powder-coated)

Vibration-resistant feet

Adjustable feet

|

|

|

|

|

|

|

|

|