Do you need a balance that not only determines weight with impressive accuracy, but also performs a digital audit, responds to your voice commands and sends you light messages?

5Y Terminal

With Terminal 5Y you get a 10-inch display, Digital Weighing Auditor, multi-step user verification, ambient light alerts, hotspot, RFID*, live note voice and text notes, voice commands for the balance and handy measurement history within the handy library widgets

Digital Weighing Auditor

Ensures that your balance is ready for use. It enables air buoyancy compensation in real-time. What is more, it informs about the need for a balance inspection or a periodic audit of the balance’s accuracy and sensitivity

10-Inch Display

Bigger screen – 10 in – means more information in one place. On the new ELLIPSIS terminal, you will see up to 3 screens, widgets, graphs, statuses, notes, handy measurement history.

Uncompromising User Verification

For the first time ever, the balance will verify the user using a password, RFID card, fingerprint reader, facial recognition mechanism, or any combination of these.

Ambient Light – An Innovative Way for the Balance to Communicate With the User

The light colour will tell you about status, process results, procedures, or alerts

Hotspot

Use the balance on any device connected to it. This can be a smartphone, tablet, or computer.

RFID

ELLIPSIS works with RFID tags* that can be used to tag your products or formulation ingredients in the database. They can also be used to identify a use

Live Note – Note Down Your Conclusions

It’s the first time you can add a voice memo to a measurement series or procedure report. If you prefer to write it down, ELLIPSIS allows you to add a text note.

Handy Library

This is where a series of recent measurements or a report ready for digital signature, according to 21 CFR Part 11, can be found.

Widgets

Prepared to display what you need most at any given moment.

Smart Min Weight

The balance displays whether the value of the weight you want to weigh is below or above the minimum weight threshold.

21 CFR Part 11

Do you work in the pharmaceutical industry?

Do you need a digital signature?

We are offering the laboratory balance which as a standalone fully meets the requirements of 21 CFR Part 11/ EU GMP Annex 11. Call us for more info before you order

- Full data security

- Electronic signatures

- Validations

- Electronic records

- Audit trails

Modbus TCP/IP

is one of the most popular communication protocols in industrial automation. Implementing it in the 5Y balances and CY10 scales makes the devices of this series friendly to automation integrators.

A balance or scale in a Modbus system is a slave device and performs tasks specified by the master device which is most often a PLC. Protocol Modbus TCP/IP in the 5Y balances and C10 scales enables, among other things, the realization of mass readout, zeroing and tare functions of the device, as well as tare settings and MIN and MAX thresholds.

Two-point adjustment

Adjacency, which takes place at two measurement points instead of one, improves measurement precision over the full weighing range. And what does this mean for you? More accurate measurement.

Under-pan weighing

Weighing instruments purchased after 15th February 2023 will allow under-pan weighing at any time after the purchase. All you need to do is just to order a dedicated hook.

Functions

- Autotest

- Dosing

- Percent Weighing

- Parts counting

- Peak hold

- Formulation

- Statistics

- Checkweighing

- IR sensors

- GLP Procedures

- Animal weighing

- Pipettes Calibration

- Air density correction

- Density determination

- Differential weighing

- Ambient conditions monitoring

- Statistical Quality Control

- Packaged Goods Control

- ALIBI Memory

- Wi-Fi®

| Standard Model |

PS 200/2000.5Y

WL-220-0418 |

PS 210.5Y

WL-220-0408 |

PS 360.5Y

WL-220-0412 |

PS 600.5Y

WL-220-0414 |

PS 750.5Y

WL-220-0416 |

PS 1000.5Y

WL-220-0406 |

PS 3000.5Y

WL-220-0410 |

$2,766.00

|

$2,435.00

|

$2,460.00

|

$2,490.00

|

$2,522.00

|

$2,700.00

|

$4,025.00

|

| Capacity x Readability |

200 g x 1 mg

2000 x 0.01 g |

210 g x 1 mg |

360 g x 1 mg |

600 g x 1 mg |

750 g x 1 mg |

1000 g x 1 mg |

3000 g x 1 mg |

| Tare range |

-2000 g |

-210 g |

-360 g |

-600 g |

-750 g |

-1000 g |

-3000 g |

| Standard repeatability [5% Max] |

0.5 / 5 mg |

0.5 mg |

0.5 mg |

0.5 mg |

0.5 mg |

0.5 mg |

0.6 mg |

| Standard repeatability [Max] |

1 / 10 mg |

1 mg |

1 mg |

1.5 mg |

1.5 mg |

1.5 mg |

1.5 mg |

| Standard minimum weight (USP) |

1 g |

1 g |

1 g |

1 g |

1 g |

1 g |

1.2 g |

| Standard minimum weight (U=1%, k=2) |

0.1 g |

0.1 g |

0.1 g |

0.1 g |

0.1 g |

0.1 g |

0.12 g |

| Linearity |

+2 / 20 mg |

+2 mg |

+2 mg |

+3 mg |

+3 mg |

+3 mg |

+6 mg |

| Stabilization time |

2 / 1.5 s |

2 s |

2 s |

2 s |

2 s |

2 s |

3 s |

| Adjustment |

internal (automatic) |

| Leveling system |

semi-automatic - LevelSENSING |

| Delivery components |

Balance, weighing pan, weighing pan shield, grounding bumper ×1, bumper ×3, power supply. |

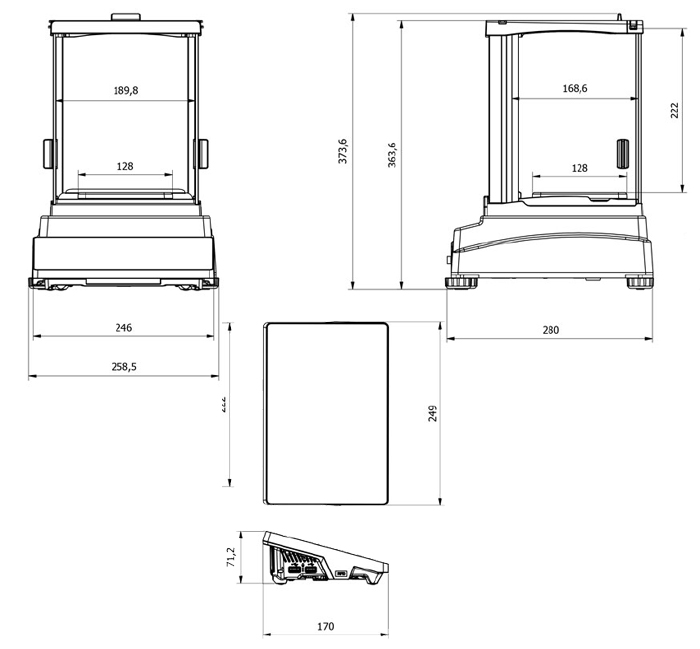

| Weighing pan dimensions |

128×128 mm |

| Packaging dimensions |

600×400×550 mm |

| Net weight |

3,99 kg |

3,54 kg |

3,99 kg |

3,99 kg |

3,9 kg |

4,01 kg |

3,9 kg |

| Gross weight |

5,5 kg |

5 kg |

5 kg |

5,5 kg |

5 kg |

5 kg |

5,5 kg |

| Protection class |

IP 43 |

| Database capacity |

7 |

| Touch-free operation |

2 IR Sensors |

| Communication interface |

2×USB-A, USB-C, HDMI, Ethernet, Wi-Fi, Hotspot |

| Power supply |

Adapter: 100 – 240V AC 50/60Hz 0,6A; 12V DC 1,2A Balance: 12 – 15V DC 0,8A max |

| Power consumption |

4 W |

| Operating temperature |

+10 ÷ +40 oC |

| Ambient conditions monitoring (option) |

THBR 2.0 System, THBR BOX, THB P, THB W, THB S |

| Relative humidity |

40% ÷ 80% |

Repeatability is expressed as a standard deviation from 10 weighing cycles. Stabilization time depends on the ambient conditions and the

dynamics of weighing pan loading; specified for FAST profile. 1 Barcode scanners, available as weighing instrument accessory,

| Standard Model |

PS 2100.5Y.M

WL-220-0409 |

PS 3500.5Y.M

WL-220-0411 |

PS 4500.5Y.M

WL-220-0413 |

PS 6100.5Y.M

WL-220-0415 |

PS 8100.5Y.M

WL-220-0417 |

PS 10100.5Y.M

WL-220-0407 |

$2,460.00

|

$2,500.00

|

$2,549.00

|

$2,577.00

|

$2,772.00

|

$2,982.00

|

| Capacity x Readability |

2100 x 0.01 g |

3500 x 0.01 g |

4500 x 0.01 g |

6100 x 0.01 g |

8100 x 0.01 g |

10100 x 0.01 g |

| Tare range |

-2100 g |

-3500 g |

-4500 g |

-6100 g |

-8100 g |

-10100 g |

| Standard repeatability [5% Max] |

5 mg |

5 mg |

5 mg |

5 mg |

5 mg |

5 mg |

| Standard repeatability [Max] |

8 mg |

8 mg |

8 mg |

8 mg |

10 mg |

12 mg |

| Standard minimum weight (USP) |

10 g |

10 g |

10 g |

10 g |

10 g |

10 g |

| Standard minimum weight (U=1%, k=2) |

1 g |

1 g |

1 g |

1 g |

1 g |

1 g |

| Linearity |

+20 mg |

+20 mg |

+20 mg |

+20 mg |

+20 mg |

+20 mg |

| Stabilization time |

1.5 s |

1.5 s |

1.5 s |

1.5 s |

1.5 s |

1.5 s |

| Adjustment |

internal (automatic) |

| Leveling system |

semi-automatic - LevelSENSING |

| Delivery components |

Balance, weighing pan, weighing pan shield, power supply |

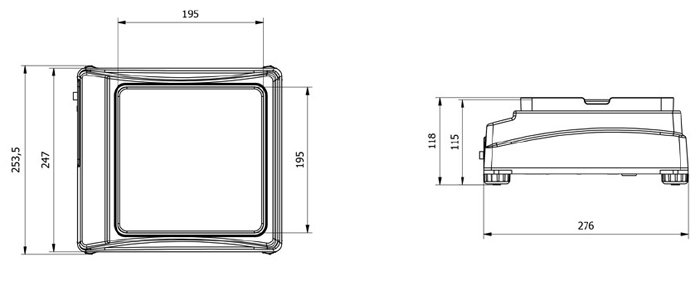

| Weighing pan dimensions |

195x195 mm |

| Packaging dimensions |

720×370×274 mm |

| Net weight |

7.2 kg |

7.2 kg |

7.2 kg |

7.2 kg |

7.2 kg |

7.2 kg |

| Gross weight |

9.3 kg |

9.3 kg |

9.3 kg |

9.3 kg |

9.3 kg |

9.3 kg |

| Protection class |

IP 43 |

| Database capacity |

7 |

| Touch-free operation |

2 IR Sensors |

| Communication interface |

2×USB-A, USB-C, HDMI, Ethernet, Wi-Fi, Hotspot |

| Power supply |

Adapter: 100 – 240V AC 50/60Hz 0,6A; 12V DC 1,2A Balance: 12 – 15V DC 0,8A max |

| Power consumption |

4 W |

| Operating temperature |

+10 ÷ +40 oC |

| Ambient conditions monitoring (option) |

THBR 2.0 System, THBR BOX, THB P, THB W, THB S |

| Relative humidity |

40% ÷ 80% |

Repeatability is expressed as a standard deviation from 10 weighing cycles. Stabilization time depends on the ambient conditions and the

dynamics of weighing pan loading; specified for FAST profile. 1 Barcode scanners, available as weighing instrument accessory,

Old 3Y Models

The PS 3Y Series Precision Balance features a 5.7” TFT color touch screen display for easy operation and presentation of measurement results. The balance allows for customized setting along with user profiles. A balance protective cover is a standard offering for this series.

The 3Y series comprises an automatic internal adjustment system using an internal mass standard. The balance level is monitored by the LevelSENSING system - a RADWAG patented solution including an electronic level. A new feature of the 3Y series is on-line ambient condition monitoring using either internal sensors or the external module THB 3 Series. A newly implemented differential weighing mode enables weighing of loads subject to process changes over time.

Extended databases of the 3Y Series balances allow for measurement archiving along with print and export functions. Both standard and user defined printouts are available; and editable templates allow for documentation according to GLP/GMP standards for practically in any organization.

The 3Y Series features an independent mass control mode in conjunction with the PA-02/H Series Automatic Feeder.

ELECTRONIC LEVEL INDICATOR

Functions:

- ALARM (out of tolerance notification)

- graphic level indicator

- programmable acceptable tilts

DATA EXCHANGE THROUGH USB STORAGE DEVICES

- update balance software

- export weighing data

- export/import databases

- export/import balance settings

- exchange data between balances

INFRARED PROXIMITY SENSORS

Functions:

- PRINT function

- TARE function

- sensors sensitivity adjustment

COMMUNICATION INTERFACES

- Ethernet

- 2xRS 232

- 2xUSB

- additional display port

PORTABILITY

Extra option: Balances with a wireless terminal

FUNCTIONS

- AUTOTEST - Diagnostic function aiming at metrological parameters determination (repeatability), the parameters are determined for the actual conditions of use. When speaking of repeatability it may be also used for weighing time optimization. Autotest is operated in an automatic mode thus operator’s time is saved.

- CHECKWEIGHING - Checkweighing function is used for checking whether the measured sample mass is within the predefined threshold values, Low [LO] and Hgh [HI]. The thresholds are given in [g] and [kg] units. Current state of a sample being measured is signalled by means of pictorgams located on a display for laboratory balances, for industrial scales Stackligt System is used. This visual /- inspection is in operation during segregation, control or packing process of products for which mass has bees determined with a specifaied tolerance, eg. 12860 g 961

- DOSING - Weighing process for which reference mass has been determined together with tolerance for its determination. Dosing tolerance is given in [%] and it is calculated in relation to the reference value thus being a permissible deviation of this process. This solution is used for weighing powders, liquids and loose materials. Dosing function performance is often supported with bargraph - load indicator. For industrial scales it is possible to use a control systems of dosing process

- PARTS COUNTING - Function using mass measurement for determination of measured items quantity. Mass of a single item is required for this process. It may be either estimated through weighment or taken from a database. For items counting the following algorithm is used: all items mass / single item mass = quantity. Function operation is supperted by a mechanism of Automatic Correction of Accuracy. This allows to update single item mass in course of the process. To a certain extend Automatic Correction of Accuracy eliminates error which may be a result of different mass values of seemingly alike single elements. For industry solutions items counting may be simultaneously carried out with checkweighing and dosing thus industry solutions feature audio signalling base informing that specified number of items has been weighed. It is possible to apply weighing systems using few platfroms of different MAX capacities and different accuracies.

- PERCENT SETUP - Percent setup function is used for comparision of measured products with mass standard. Mass of a mass standard may be a numeric value taken from a database or it may be determined through a measurement process. Each measured product is compared to mass standard, mass of which is presumed as a model 100% ideal mass. For products weighing less than the mass standard, obtained results are lower than 100%, for products weighing more, the obtained results are greatly excessed.

- GLP PROCEDURES - Diagnostic function allowing to objectively document performed measurements. GLP procedures may be either presented in a short report form or extended one.

- FORMULATION - Function supporting the mixture making process, wherein the mixture contains various components. Formulation function usually uses the balance/scale database of components. Formulation serves for monitored checkweighing of every single component with a given tolerance. It is enriched with a set of individual settings.

- IR SENSORS - Programmable function supporting the weighing process through control of the following options: sliding weighing chamber doors, printout, zeroing, tarring etc. Especially appreciated wherever preventing the balance from soiling is important

- STATISTICS - Statistiscs function registers and analyses performed measurements. This supplies the user withthe following information: Max and Min standard deviation, average value, variance, range et.

- ANIMAL WEIGHING - Process of mass determination for a product which may unwillingly reposition within the weighing pan. Mass determination in such cases requires much longer period of time when compared to typical weighing process. It is the user who defines period of time needed for control of measured product mass. The user can thus optimaze the function depending on the measured product characteristics.

- DENSITY DETERMINATION - Liquid or solid body density function uses the Archimedes principle and it requires a special kit to be applied. The kit when used, replaces a weighing pan. For solids mass of the sample must be determined first in the air, next in the liquid of specified density. For liquids the so called sinker, density of which has been determined, must be measured first in the air, next in the tested liquid. The density determination process is disturbed by air bubbles which may stick either to the measured sample or the sinker. In case of laboratory equipment very light solids may be measured. For industry, solid bodies density may be determined by means of under-pan weighing. Tested load of significant size may be measured this way.

- UNDER HOOK WEIGHING

| Standard Model |

PS 450.3Y |

PS 1000.3Y |

PS 4500.3Y.M |

PS 6100.3Y.M |

PS 8100.3Y.M |

PS 10100.3Y.M |

$2,413.15

|

$2,993.70

|

$2,406.35

|

$3,177.30

|

$3,609.10

|

$3,991.60

|

| Capacity x Readability |

450 g x 1 mg |

1000 g x 1 mg |

4500 g x 0.01 g |

6100 g x 0.01 g |

8100 g x 0.01 g |

10100 g x 0.01 g |

| OIML Capacity x Readability |

450 g x 0.01 g |

1000 g x 0.01 g |

4500 g x 0.1 g |

6100 g x 0.1 g |

8100 g x 0.1 g |

- |

| OIML Class |

II |

II |

II |

II |

II |

- |

| MonoBLOCK® |

- |

- |

YES |

YES |

YES |

YES |

| Tare range |

-450 g |

-1000 g |

-4500 g |

-6100 g |

-8100 g |

-10100 g |

| Linearity |

+2 mg |

+3 mg |

+0.03 g |

+0.03 g |

+0.03 g |

+0.03 g |

| Repeatability (5% Max)* |

0.0005 g |

0.0005 g |

0.005 g |

0.005 g |

0.005 g |

0.005 g |

| Repeatability (Max) |

0.001 g |

0.001 g |

0.008 g |

0.008 g |

0.01 g |

0.012 g |

| Sensitivity drift |

2 x 106 / oC x Rt |

| Working temperature |

+10 - +40 oC |

| Minimum weight (USP) |

1 g |

10 g |

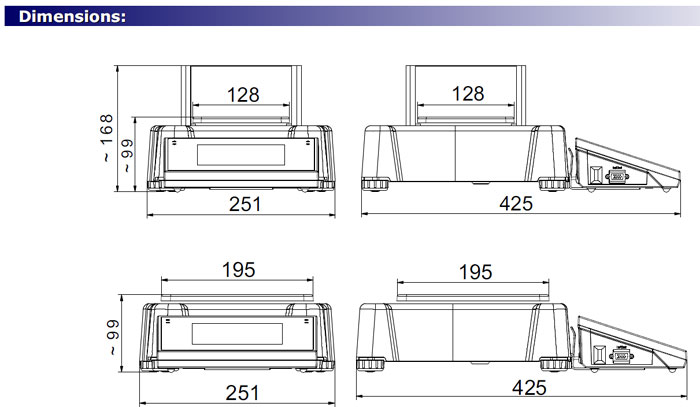

| Pan size |

128x128 mm |

195x195 mm |

| Stabilization time |

2 s |

1.5 s |

| Display |

5.7" touch panel |

| Power supply |

13.5 ÷ 16 V DC / 2.1 A |

| Interface |

2xUSB, RS 232, Ethernet, 4Inputs/4Outputs |

| Adjustment / Calibration |

internal (automatic) |

| Casing of the terminal |

ABS plastic |

| Net weight/Gross weight |

4.1/7.1 kg |

5.6/8.2 kg |

6.8/9.4 kg |

* repeatability is expressed as a standard deviation from 10 weighing cycle

Additional equipment

- Anti vibration table for laboratory balances

- Printer Epson, Citizen

- Foot button for tare or print functions

- Density determination kit for solids and liquids

- PC USB keyboard

- Anti draft shield

- Bar code scanner

- THB 3 ambient conditions module

- Automatic feeder PA-02/H

- Mass standard

- LCD display WD-5

- Power adapter with battery and charger ZR-02

- Power loop output AP2-1 (plastic version)

- Antistatic cable PA 1

- Computer software: PW-WIN, RAD-KEY

- Cable: P0136, P0151

|